Industrial Revolution Facts and Information

The Industrial Revolution might have ended over a century ago, but it’s still relevant today as it embodies many of humanity’s greatest characteristics.

Traits that in a world of rapidly dwindling fossil fuels, fragile national economies and ever-increasing populations are going to be crucial in tackling the problems that lie ahead.

Ingenuity, tenacity and scientific knowledge drove the Industrial Revolution and created a better world for the billions of people alive today. That noble ability to enrich the lives of future generations is something worth celebrating.

THE STEAM AGE

It’s a common misconception that steam is visible. The characteristic white mist that we see rising from a boiling kettle or the cooling tower of a power station is, in fact, haphazard clouds of water droplets forming through the condensation of steam in the cooler air. Indeed, if steam was simply a mist of water droplets and nothing more, it wouldn’t be anywhere near as exciting as we’re about to reveal.

No, true steam – generated when water molecules receive an energy excess great enough to break down their bonds – is of interest due to the massive growth in volume brought about by its phase change. This expansion clocks in at 1,700 times the volume of its liquid state (water) – a factor of 30,600:18. As such, a single mole of water – a mole of a substance is the mass of the material in grams that is numerically equal to its molecular mass – is 18 grams. However, at standard temperature and pressure, that mole expands to fill a volume of 22.4 litres when vaporized. Conversely, the same factor is attributable to the reversed state change (ie condensation).

This process is far from merely a scientific curiosity. It is fundamental to understanding how arguably the biggest social, industrial and economic upheaval the world has ever witnessed came to bear over a period of 200 years. That upheaval was the Industrial Revolution and that simple, invisible, beautiful expansion of volume was the driving factor of the steam engine – one of the most important inventions ever created and the machine that essentially built the modern world.

This process is far from merely a scientific curiosity. It is fundamental to understanding how arguably the biggest social, industrial and economic upheaval the world has ever witnessed came to bear over a period of 200 years. That upheaval was the Industrial Revolution and that simple, invisible, beautiful expansion of volume was the driving factor of the steam engine – one of the most important inventions ever created and the machine that essentially built the modern world.

Key dates of the steam age

Chart some of the most game-changing inventions, developments and discoveries over 200 years:

1701 Tull’s seed drill – Jethro Tull’s seed drill embodies the shift from an agrarian economy to one dominated by urban industry and machine manufacture.

1712 Newcomen engine – Thomas Newcomen’s engine is an early glimpse into the possibilities of steam power. It’s used mainly to drain mines of water, but will later be adapted to do much more.

1733 Flying shuttle – The invention of the flying shuttle in the mid-18th century allows for a much larger-scale weaving of fabrics. It is eventually automated in machine looms.

1764 Spinning jenny – This spinning machine reduces the amount of work needed to produce yarn, allowing for multiple spools to be created at once, increasing efficiency.

1772 Bridgewater Canal – The successful completion of the Bridgewater Canal in north-west England kicks off the rapid expansion of a canal network throughout the UK.

1775 Watt steam engine – James Watt’s engine markedly improves on Newcomen’s design from 60 years earlier, using steam at a pressure just above atmospheric to drive a piston.

INDUSTRIES TRANSFORMED

The invention of the steam engine and its practical implementation in the beam engines of the early-18th century was the catalyst. By mechanizing and automating the excavation of mines, not only could raw materials – such as coal and ores – be harvested in immense quantities, but the process could be executed at a speed simply infeasible for manual labourers. Soon, the rapidly increasing availability of coal and raw building materials allowed ever-more complex machines to be invented, housed in greatly upscaled industrial buildings like factories.

The invention of the steam engine and its practical implementation in the beam engines of the early-18th century was the catalyst. By mechanizing and automating the excavation of mines, not only could raw materials – such as coal and ores – be harvested in immense quantities, but the process could be executed at a speed simply infeasible for manual labourers. Soon, the rapidly increasing availability of coal and raw building materials allowed ever-more complex machines to be invented, housed in greatly upscaled industrial buildings like factories.

Everything was affected. From agriculture through to metal working and construction, and on to the textile industry, the fuel surplus enabled more and more steam engines to be built, which in turn allowed more and more machines and processes to be automated. Workers who had till then found themselves confined to their area of birth were released from this geo-economic prison by roads, bridges, plus quicker and cheaper transport.

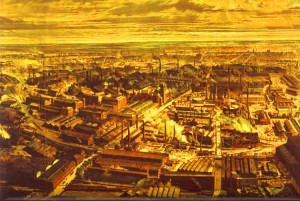

This expansion – not just industrially but socially and commercially – essentially led to the collapse of the existing social structure, with a wider distribution of wealth generating extra tiers within a nation’s class system. It also led to the creation of modern industrial cities, with many industries increasingly bound by a mutual reliance on each other’s trade and, importantly, the machines and power source (steam produced by coal) that, year by year, was becoming the norm.

The beam engine

This invention allowed mines to be cleared of water mechanically, so coal and ores could be excavated quicker than ever before.

The beam engine was used to draw out water from mines, as well as to pump water into canals. The engine consisted of a large wooden frame into which a pivoted overhead beam was used to apply force generated by a vertical piston and transfer that movement to a pump rod.

The piston’s movement was driven by a coal-heated boiler, which generated steam and fed it into the piston’s cylinder. When the piston was at its apex – moving the beam and dropping the pump rod – the cylinder was injected with cold water, creating condensation and eventually a vacuum, thereby drawing the piston down and raising the pump rod again in a cycle. Early beam engines (eg Newcomen’s) were quite inefficient due to their lack of a separate condenser.

Watt’s steam engine

James Watt brought steam to the masses, allowing industries to upscale and automate their operations.

James Watt brought steam to the masses, allowing industries to upscale and automate their operations.

The Watt steam engine made two critical improvements to existing models. The first was the addition of a separate condenser cylinder alongside the main piston cylinder. This meant that the majority of condensation – and therefore vacuum creation – took place outside the heated drum. This allowed the main piston cylinder to remain at a temperature where water could quickly be pressurised. The second improvement was the introduction of an extra steam valve. The added valve increased the power of the engine as it capped and inserted low-pressure steam into the upper part of the main piston cylinder. This sped up vacuum creation, increasing the piston’s downstroke power and, as a result, its actions per minute.

The Thames Tunnel

The first tunnel to be built under a navigable river, this was one of Brunei’s engineering milestones.

The Thames Tunnel introduced the tunneling shield. This consisted of three iron frames mounted on top of one another like an open-backed bookcase. This structure was placed against the area of earth that needed to be excavated and then workers proceeded to dig in its cavities, removing soil in sections. Once the distance of the cavities had been excavated, it was shunted forward by a series of screw braces. This meant that at each stage of the dig the shield supported the walls and ceiling, allowing time for masonry reinforcements to be installed.

Iron Bridge

The first-ever arch bridge to be made purely from cast iron.

The Iron Bridge, in Shropshire, UK, consists of 482 main iron castings, which were forged at the Bedlam Furnaces 500 metres (1,640 feet) downstream and shipped by reinforced barges to the site. The construction of the huge iron components was made possible by improvements to furnace, moulding and pressing equipment, with many parts needing to be heavily bowed, such as the structure’s five parallel arch frames. After a complex assembly process, the road surface was finished with clay and blast furnace slag.

The voltaic pile

The world’s first electric battery, made by Alessandro Volta, led to a boom in electrochemical power supplies and the discovery of electrolysis.

The world’s first electric battery, made by Alessandro Volta, led to a boom in electrochemical power supplies and the discovery of electrolysis.

The voltaic pile was a set of individual electrochemical cells placed in a stack separated by an electrolyte, such as pasteboard soaked in brine. When both ends of the tower were connected with wire, it generated an electric current. The pile produced a charge due to molecular reactions, involving each zinc disc being partially dissolved by the acidic brine disc, leading to zinc atoms losing two electrons each. The zinc atoms became ions, passing into the brine disc and coming into contact with a silver or copper disc on the other side, where their lost electrons were replaced. This generated excess electrons within the zinc disc that would travel through the cell and replace the electrons stolen by the zinc atoms from the silver disc. This continuous flow of electrons created a steady current, which had eluded scientists for many years.

RISE OF THE MACHINES

The Industrial Revolution saw machines put centre stage due to their ability to perform tasks at a literally inhuman rate. Manual workers found they were no longer craftspeople, but operators of steam hammers, water frames, power looms and more. They operated many of these steam-powered devices in factories – a new system of production also born in this period.

Prior to the 1700s the majority of industries were ‘cottage industries’, with small groups of craftspeople taking part in heavily localized operations producing limited goods. Taking the textiles industry as an example, wool and cotton fibres were spun by hand into yarn and weavers turned them into bespoke items for a select few wealthy clients. However, with the advent of spinning frames and mechanized looms, these craftspeople were drawn together in a factory setting, with items created en masse. Due to the removal of hands-on skill in many of their roles, more untrained workers could be hired.

The scale of the integration of industrial machinery can’t be overstated. Every level of the textiles industry was transformed, with cotton engines allowing fibres to be separated from seeds rapidly, spinning frames enabling those fibres to be spun into yarn on a massive scale, and power looms driven by vast drive shafts allowing cloth to be weaved with unprecedented efficiency.

While the first half of the Industrial Revolution, circa 17001830, was characterised by stationary steam-powered machines, the second half (circa 1830-1900) saw an explosion in machines that moved. It was kick-started by Richard Trevithick’s steam-powered locomotive and carriage, and then refined by a series of inventors who took mobile applications of the steam engine to another level. Soon steam-powered trains (like Stephenson’s rocket), carriages, balloons and ships were opening up the possibility of long-distance travel across the globe.

The steam hammer

One of the many machine tools invented during the Industrial Revolution, James Nasmyth’s steam hammer took forging to a whole other level.

One of the many machine tools invented during the Industrial Revolution, James Nasmyth’s steam hammer took forging to a whole other level.

The steam hammer was essentially a power hammer, as used today to shape forgings, but it was driven by a steam engine. It comprised a hammer-like piston within a cylinder positioned vertically in an iron frame. The central hammer piston was driven upwards by injecting high-pressure steam into the cylinder’s base, which was supplied by an adjacent coal boiler. Once the hammer had been raised, the metal that needed forging was placed underneath on an iron bed. The steam at the bottom of the cylinder was then ejected rapidly via a condenser, creating a vacuum that, combined with gravity, caused the hammer to drop quickly onto the metal, shaping it as desired. Later, the drop speed of the hammer was further increased by injecting high-pressure steam into the top of the cylinder at the same time.

Despite its simple operation, the steam hammer gained huge traction in the metalworking industry, allowing machines to build other machines, structures and components at great speed. In addition, the technology of the steam hammer also saw application in a range of other mechanized tools including the first automatic piledriver, a piece of engineering that reduced the time it took to install piles from several hours to just minutes.

The Bessemer converter

The invention that allowed steel to be produced in vast quantities.

The Bessemer converter was a machine and surrounding process that involved the removal of impurities from pig iron (a type of iron with a high carbon content) and its conversion into steel – a material that had historically been costly and time consuming to manufacture. The key principle behind its operation was the removal of impurities such as silicon, manganese and carbon through oxidation, turning the brittle, largely unusable pig iron into very useful steel. The oxidation of impurities occurred in a Bessemer converter, a large egg-shaped container in which the iron was melted. The solid iron was inserted through a hole at the top and heated from the bottom. Once the converter had melted the pig iron, pressurised air was injected through and across the liquid metal, forcing the unwanted silicates to react with oxygen and convert into gas and/or solid oxides (ie slag). Once the oxidation process had taken place, the usable molten steel could be poured out from the container directly by tipping it on a central pivot – the container was suspended off the ground by a pair of large struts – while the slag could be skimmed off the surface for reuse or disposal. The steel was emptied into large moulds, where it could be set into a wide range of products.

The spinning frame

Over the 18th century, spinning technology went through a great metamorphosis that would revolutionize the textiles industry.

Over the 18th century, spinning technology went through a great metamorphosis that would revolutionize the textiles industry.

The spinning jenny, the original spinning frame made by James Hargreaves in 1764, worked by twisting bundles of fibres into thread and winding it onto spindles for looms. The jenny’s mechanical action was generated by a hand crank, which was turned to produce the twisting motion In 1768 Richard Arkwright’s spinning frame hugely improved the speed at which thread could be produced. It was enhanced again by Arkwright’s water frame. The latter worked largely the same way as the previous spinning frame, but the power for the mechanical parts came from a water wheel rather than a manual crank. This greatly reduced the number of workers needed to make thread.

The cotton gin

Saving thousands of hours of manual labour, this machine turned the cotton industry on its head.

The cotton gin – short for cotton engine – consisted of a small wooden box-frame in which a wooden cylinder was surrounded by a spiked metal mesh. On the outside of the frame, the cylinder was attached to a hand crank that, when rotated, would cause the cylinder to spin. The rotating motion picked up raw cotton balls from a hopper and pulled them through the metal mesh, drawing the cotton lint into thin fibres and collecting the seeds at the same time.

DRIVE TOWARDS GLOBAL TRAVEL

Beginning in the UK but soon spreading throughout Europe, America and many other parts of the world, these new mobile machines led to the creation of vast new transport networks. New roads were constructed to accommodate carriages, new railroads built to carry steam trains laden with food, coal and produce, new canals were built on a grand scale between major industrial cities, and new laws were passed to allow inventors to trial machines that could fly for miles in the skies, or cruise silently beneath the ocean waves. These advances expanded the availability of labour, raw materials and products massively, and drew people together like never before.

Of course the age of steam and steam-powered inventions couldn’t last for long in the enlightened, driven mindset it had indirectly spawned. The rise of science and engineering culturally, as well as the increasing knowledge of material science, led to the creation of new forms of energy and explosive new prime movers. The electric battery was invented and the electric motor was derived from it; before the close of the 19th century the internal combustion engine had fired up, driven by the development of petrol and diesel.

These new power sources took mechanical engineering to another level, allowing devices such as the incandescent lamp, phonograph, electrical telegraph, telephone, automobile and aeroplane to not just be invented, but produced and implemented across the globe on a scale that was almost inconceivable.

The expansion was unstoppable and, by the end of the 19th century, most western countries were all but unrecognizable from the nations they had been at the turn of the 18th. Cities were packed with machines, vehicles, businesses, people and, crucially – indeed, the greatest legacy of the entire movement – knowledge on a truly industrial scale. It was a newfound general level of understanding that would see the world transform through the 20th century into the one we live in today. So, you see, we weren’t exaggerating when we said steam really is quite interesting…

Stephenson’s Rocket

Although not the first steam train to be built during the Industrial Revolution, Stephenson’s Rocket incorporated lots of advanced technology into one vehicle.

Although not the first steam train to be built during the Industrial Revolution, Stephenson’s Rocket incorporated lots of advanced technology into one vehicle.

The father and son made Stephenson’s Rocket was such a success as it drew together five key innovations. The first innovation was a single pair of driving wheels with a small carrying axle behind which allowed the weight of the coupling rods to be significantly reduced. In addition, as 2.5 tons of the Rocket’s total 4.2-ton weight was positioned over the forward driving wheels, the second axle could be smaller -again cutting weight. This reduction improved speed and efficiency, the latter bolstered by the Rocket’s use of a multi-tube boiler array. By installing 25 copper fire tubes instead of a single large tube to carry exhaust gases from the firebox to the chimney, a much bigger area of hot piping was created, and consequently more steam. The integration of a blastpipe aided the extra steam generated by feeding exhaust steam from the train’s cylinders into a smokebox beneath its chimney; this boosted the intensity at which air was drawn through the system. This increase in raw steam power was bolstered by the separation of the enlarged copper firebox from the boiler. The final major innovation on the Rocket was the positioning of its two cylinders at a close to horizontal angle. By arranging the cylinders this way – with their pistons powering a pair of drive wheels – the train was able to eradicate an uneven swaying motion which had been a big problem on previous vehicles.

The London Steam Carriage

The world’s first self-propelled, passenger-carrying vehicle introduced the possibility of horseless travel.

Replacing horses as a means of power required the carriage to be raised from its traditional position near the ground in order to accommodate the engine and gearing. The engine used high-pressure steam to drive a single cylinder and piston, which in turn powered a crankshaft. The linear motion produced by the piston was converted by the crankshaft into rotational motion and transferred into a spur gear, which turned the axle of the driving wheels. On top of this, the crankshaft powered the engine’s steam cocks, force pump and firebox bellows as well.

Unique to the design was the addition of a forked piston rod, which effectively closed the gap between the piston head and crankshaft. Another innovation was the use of a valve gear, allowing for the carriage’s flywheel to be scaled down, improving efficiency and top speed.

The Nautilus submarine

The inspiration for Jules Verne’s famous fictional sub, Robert Fulton’s Nautilus was the first practical submarine to be built

The inspiration for Jules Verne’s famous fictional sub, Robert Fulton’s Nautilus was the first practical submarine to be built

The Nautilus consisted of an ellipsoid tube of iron ribs covered by a series of riveted copper sheets; it measured 6.5 metres (21.3 feet) in length. The hollow body acted as the vessel’s ballast tank, with water let in or pumped out to rise or descend. Steering was taken care of by rear-mounted rudders, as well as a large manually operated hand crank. This crank was directly connected to an external screw propeller, which gave a top speed of 3.2-4.8 kilometres (two to three miles) per hour. On the top of the hull was a collapsible mast that on the surface could be set up to travel by conventional wind power, while on the bottom were two drag mines which could be used as weapons.

The Giffard dirigible

Discover the first-ever airship to be powered by a steam engine.

The 1852 Giffard dirigible consisted of a 44-metre (144-foot)-long hydrogen balloon that was encircled by a rope matrix. From the matrix hung a single metal pole which supported a gondola. The gondola was installed with a steam engine capable of producing just 2.2 kilowatts (three horsepower) that could turn the dirigible’s large, gondola-mounted propeller at around 110 revolutions per minute.

INVENTING THE FUTURE

While the first half of the Industrial Revolution saw widespread changes to manufacturing and factory processes, the second built on that solid base, spawning a variety of world-changing inventions. The scope and purpose of these inventions was different to anything before, exploiting the newfound scientific understanding of physics and chemistry to create devices that would benefit people’s day-to-day lives. Here are some of the most notable…

Induction motor

With this device, Tesla took previous electric motors to a whole new level.

With this device, Tesla took previous electric motors to a whole new level.

Prior to Nikola Tesla’s invention of the polyphase induction motor, traditional dynamos had used a stationary stator to provide a constant magnetic field through which a set of rotating windings would turn. However, by reversing this process – so that the stator magnets rotated, rather than the rotor (windings) – current could be induced to flow through the latter with far greater efficiency. This was achieved by Tesla in 1887 with a two-phase induction motor that featured a rotating stator with two pairs of magnets – one pair for each two phases of alternating current (AC).

Electrical telegraph

Radically changing the way that people communicated, the electrical telegraph helped connect the world like never before

The electrical telegraph was developed over a period of 40 years and worked by drawing together three key innovations. The first of these was the invention of the galvanometer by Danish engineer Hans Christian 0rsted in 1820. This allowed the strength of an electric current to be made visible through the deflection of an electric needle. The second innovation was the electromagnet, a device that provided a process for multiplying the magnetic force generated by a small electric current. The third and final innovation was the invention of the relay system in 1835, which could drastically amplify the strength of a signal.

Although the first electrical telegraph system was created by German scientists Karl Friedrich Gauss and Wilhelm Weber in 1833, Samuel Morse and Alfred Vail created a much more sophisticated telegraph four years later, as well as Morse code – a system of sending pulses of electrical current at different lengths down a network of metal cables. This led to the proliferation of long-distance communication throughout the USA and eventually the whole world, with the first successful transatlantic cable laid in 1866.

Bell’s telephone

Alexander Graham Bell’s telephone brought acoustic telegraphy to the masses, allowing people to talk to one another over great distances.

Alexander Graham Bell’s telephone brought acoustic telegraphy to the masses, allowing people to talk to one another over great distances.

Alexander Graham Bell’s original telephone, patented in 1876, worked by converting sound into an electrical signal via a ‘liquid transmitter’. This process centred around directing sound through a receiver and onto a thin membrane stretched over a drum. On the outside of the membrane a cork with a needle attached to a battery extended to a cup filled with sulphuric acid and a metal contact. When sound waves hit the membrane, it caused vibrations, varying the strength of the current passing between the needle and the contact. This created a varying strength electric signal that travelled down a wire to a receiver, where through a reversed process, the sounds were re-created. While not the only person to make a telephone at this time, Bell was the first to transfer his invention into a commercial product with a supporting network of exchanges and switchboards, etc.

Edison’s phonograph

An invention that resonates deeply today, Edison’s 1877 phonograph ushered in an era of recordable and reproducible audio – the forebear of modern music players.

The Edison cylinder phonograph was the first device in history that could mechanically record and then reproduce audio. It worked by receiving sounds through a brass mouthpiece and relaying them through a diaphragm to make it vibrate. The diaphragm’s vibration caused a connected stylus to make indentations on a tinfoil-wrapped, rotating drum. Once the tinfoil drum had been covered with indentations, the received audio could be played back by passing a second stylus over them, making a second diaphragm vibrate to re-create the recorded sounds. The phonograph would eventually lead to the invention of the gramophone and disc-based storage, with LP (long-play) records becoming the dominant form of audio data storage until magnetic tape, which didn’t emerge until the late-1920s. HIW Industrial Revolution