How do Electron Microscopes Work

We put these marvellous magnification machines under the microscope.

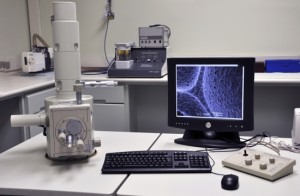

When the scanning electron microscope (SEM) was unveiled in 1935, its reception was lukewarm at best. Despite the potential to magnify objects up to 300,000 times, scientists struggled to see a commercial use for the bulky and expensive machines.

However, their application was vastly underestimated, and today more than 50,000 are in use worldwide, largely for industrial purposes. SEMs have a variety of modern-day uses, from forensics to microchip production and insect observation.

SEMs have many advantages over other methods of magnification such as optical microscopes. For example, they do not rely on light for their images, which is a major drawback of their optical counterparts. Light is unpredictable as it can diffract and bend around objects, potentially making observations very difficult. As their name suggests, scanning electron microscopes instead rely on the release of electrons to make observations.

Inside a scanning electron microscope’s casing are an electron gun, several coils, and condensing lenses that work together to observe a target sample in super-fine detail.

The core principle of an SEM is that it uses a ‘tracing’ technique to produce a replicated 3D image of the original sample being studied. It does this by scanning its electron beam over an object and measuring the electrons given off at a particular point. Using this process it can create a ‘trace’ of the object, and output an amplified image to a display. This is made possible by scanning coils, which create a magnetic field that moves the beam across the surface of the sample. The smaller the area the beam sweeps across the larger the magnification will be, and vice versa.

The core principle of an SEM is that it uses a ‘tracing’ technique to produce a replicated 3D image of the original sample being studied. It does this by scanning its electron beam over an object and measuring the electrons given off at a particular point. Using this process it can create a ‘trace’ of the object, and output an amplified image to a display. This is made possible by scanning coils, which create a magnetic field that moves the beam across the surface of the sample. The smaller the area the beam sweeps across the larger the magnification will be, and vice versa.

One of the most important aspects of using an SEM is preparing a sample for observation and ensuring that there is nothing that could hinder the final image. Samples must be thoroughly cleaned to get rid of any dust, debris or alien material not native to the sample that could skew results. The sample must also be able to conduct electricity. If it can’t, electrons will not leave its surface when struck by the beam. Objects that aren’t already conductive will be coated in a fine layer of gold or platinum in a process known as ‘sputter coating’. This also prevents the sample becoming damaged by the beam during observation.

Electron Microscope facts

Electron gun – A steady beam of high-energy electrons is fired into the machine, created either by thermal energy (thermionic guns) or electrical fields (field-emission guns).

Lenses – A series of magnetic lenses bend and focus the beam into a precise spot to ensure only a specific part of the sample is hit by the beam at any one time.

Sweep – Scanning electromagnetic coils move the focused beam across the sample in rows, so that the whole sample is subjected to the beam.

Bad vibrations – The sample is placed on a stage inside a chamber of the machine. This must be kept extremely still as SEMs are very sensitive to vibrations.

Vacuum – The inside of the microscope is a vacuum. For a sample to survive it must sometimes be specially prepared, often being coated in gold, which also enables it to conduct electricity and release detectable electrons.

Vacuum – The inside of the microscope is a vacuum. For a sample to survive it must sometimes be specially prepared, often being coated in gold, which also enables it to conduct electricity and release detectable electrons.

Anode – The negatively charged electrons are accelerated and confined into a beam by a positively charged electrode, called an anode.

Objective lens – This magnetic lens focuses the beam further onto a specific area of the sample.

Backscattered electron detector – Additional electrons are counted by another detector that determines the composition of the sample and also deduces the elements present.

Secondary electron detector – As the beam strikes the surface of the sample it knocks the electrons loose. By counting the number of electrons released, a detector can produce a magnified image of the sample.